It is not something to wonder about when it comes to sticker printing Canada as they have evolved greatly and has become quite famous with their rising popularity. The quality, as well as the durability, is nothing compared to that which can be purchased online as you can also print some basic stickers from home.

For the creation of longer-lasting stickers, there are quite a few people who have the printers along with the ink that is a necessity here.

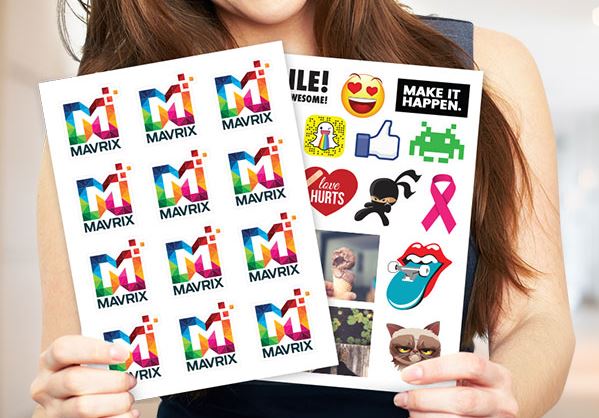

Sticker printing, like all of the technology, has vastly improved over the years. It’s no longer limited to the black on the white, rectangle, thin paper stickers, but instead prints on a variety of types and weights of paper with endless color options; not to mention the numerous shapes and sizes of stickers.

Types of Sticker Printing

Screen printing: The oldest and still most common method of printing is screen-printing. For transferring the image to that of the sticker paper, it is simplest process that uses synthetic screens. This technique is used for the production of a limited quantity of stickers as this is for some basic printing.

With the use of a stencil, the ink is squeezed through the screen on that to the paper. For each color used; a stencil for one color is cut and pressed onto the paper, the process must be repeated. For a second color and which color is pressed into it, a stencil is cut.

Sticker paper. Until all colors are transferred and the design is complete, the process is repeated.

Letterpress printing: This technique is generally a form of relief printing that utilizes a press and movable type. To get the right-sided image on to the paper, a reversed, raised surface is usually inked and pressed onto it. This is used for some smaller and basic projects that use only one color.

Flexography: A much quicker printing process, flexography allows for printing larger quantities of stickers. This technique is usually used for commercial printing. A master print is usually created that is then used for printing the image on that on the sticker for the plate that is being rolled over to that of the paper in flexography. In terms of sticker printing, this is the most advanced technique used.

Offset printing: The image transfer is made from a plate or that of the rubber cylinder and to paper in this technique.Offset printing gives the printer several color options and prints excellent color.

Four color process: The colors of the original images into that of the CMYK formats of that of cyan, magenta, yellow and black are usually used in this process as it separates the colors of the original image. For every color here different files are created and the prints are done with special inks so that the image onto the sticker would look extremely identical to that of the original image.

Digital printing: The most advanced form of printing is digital. You are able to make changes up to the last minute, including color changes. In digital printing, the ink sits on the paper as opposed to being absorbed into the paper.

Digital printing is not usually suitable for very large quantities but is mostly used for personal printing for the home or small business. However, a form of digital commercial printing sends the image directly to the press without making plates. This makes the process cleaner and quicker, but the image is still transferred with a press.

Using a Professional Sticker Printer

The durability and quality of the sticker will suffer tremendously from what you would receive from a professional sticker printer, regardless of which professional sticker printing process is used.

Professional printers can print color stickers in quantities in the tens of thousands. Professional sticker printing companies have a wide range of stickers and custom sticker options and are widely available on the Internet.

All of them are designed to make our life easier in one or another. They can be obtained in a number of ways. They can be simple or complicated. Mostly, they need some sort of marketing in order to get familiarity with the customers. A simple and easy way for this task is to use custom stickers.

Custom stickers Vancouver BC helps in many ways. They are the need of the modern world. Almost all large companies and businesses utilize personalized stickers to enhance their business identity.

They are so easy to produce and can be customized in many ways. The printing companies also offer many low coast products as well. You can get cheap sticker printing without any effort.

They have become necessary for modern marketing campaigns. They cost low and yet help in getting betting results. You can use many materials to produce them. Paper, plastic are vinyl are the most common ones.

In fact, vinyl sticker printing is very popular. By using low-cost materials, you can always get them at cheaper rates. This way you would be able to save some money while getting good cheap vinyl stickers.

They come in many varieties. They can be round in shape, rectangular in shape or of any other specific shape the customer wants.